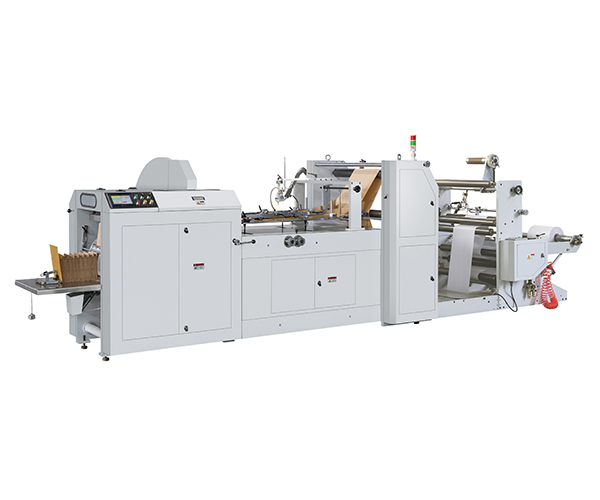

Working Flow Chart - Unwinder paper rolls feeding -epc -auto tension -Side Glue -window film roll with hot melt system -Photocell-Forming tube-Gusset -Pulling paper -Cutting -V shape forming -Bottom glue -Finished v bottom paper bags

The human-machine touch screen interface, the work condition can be shown in real- time.

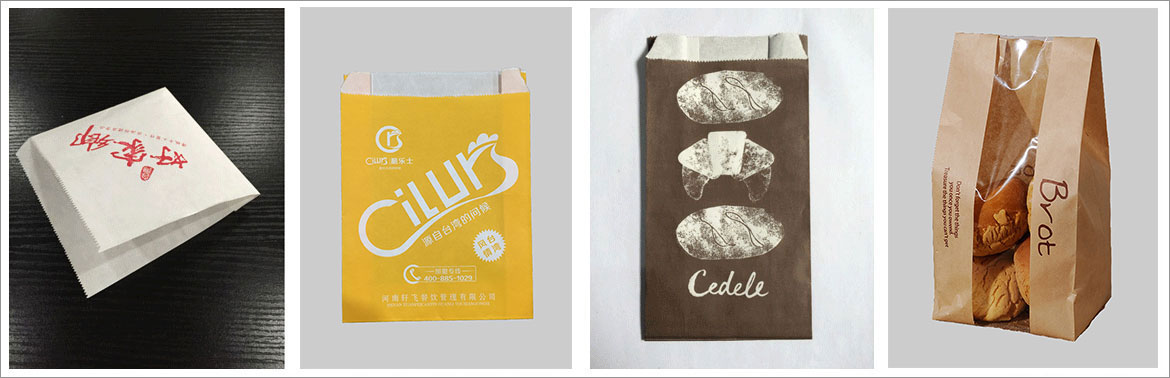

This machine froming the roll paper to the Spray adhesive, Paste the film, the top of the glue, into a tube, cut bags, folding bottom, paste the finished product bag finished once. The new model is more convenient, more efficient and more stable, fast food bags, bread bags, dried fruit bags, shopping bags, and so the ideal equipment for environmental protection paper bags.

1.The human-machine touch screen interface, the work condition can be shown in real- time.

2.Equipped with accurate servo motor drive, it makes the machine run steadily and efficiently.

3.Material lifting adopt pneumatic lift structure.

4.Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving, long life.

5.The machine has automatic counting system. The user can set a number to count.

6.Accurate color tracking system, color errors automatically shut down.

| Type | LMD-600B |

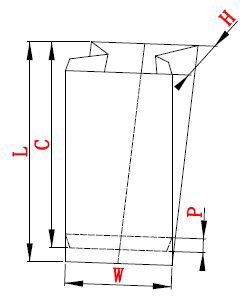

| Cutting Length(C) | 220-620 mm |

| Bag Length(L) | 210-610 mm |

| Bag Width(W) | 70-280 mm |

| Gusset Thickness(H) | 0-120 mm |

| Standard Flap(P) | 12-20 mm |

| Max.Speed | 500 pcs/min |

| Paper Thickness | 30-80 gsm |

| Paper Roll Width | 220-700 mm |

| Max.Roll Diameter | 1100 mm |

| Reel Inner Diameter | 76 mm |

| paste window unit | Yes |

| Film Thickness | 0.02-0.04 mm |

| Film Width | 50-180 mm |

| The Max Film Diameter | 450 mm |

| Film Inner Diameter | 76 mm |

| Total Power | 7 kw |

| Weight of Machine | 3800kg |

| Overall Dimension(LxWxH) | 6150×1550×1500 mm |

Note:

Machine speeds dependent on paper & adhesive qualities, bag dimensions, operator knowledge, and general work philosophy.

|

|

|

|

|

|

|

|

Hot-melt glue spraying system Hot-melt glue spraying systemHot-melt glue spraying system makes the pasted materials more stably. The bags won’t unglued keep in the cold condition. |

Automatic constant tension and rectify deviation systems Automatic constant tension and rectify deviation systemsautomatic constant tension control system. The tension will be just right from beginning to end. Automatic edge control system adopts two photoelectric sensors to detect the edge of paper web. its life is extended. |

Get A Quote !