Paper bags are widely used in retail, food packaging and a variety of industries due to their environmental friendliness and versatility. The production of paper bags requires specialized machines to ensure efficiency, durability and aesthetics. This article explores the different types of paper bag machine used to produce various paper bags, including their functions and applications.

I. Flat Paper Bag Machine

Flat paper bags are simple, lightweight bags commonly used in grocery stores, drug stores and small retail stores.

Key Features:

Produces flat, single-layer paper bags

Suitable for low to medium production runs

Can handle different weights and sizes of paper

Applications:

Small shopping bags

Takeaway food bags

Gift bags

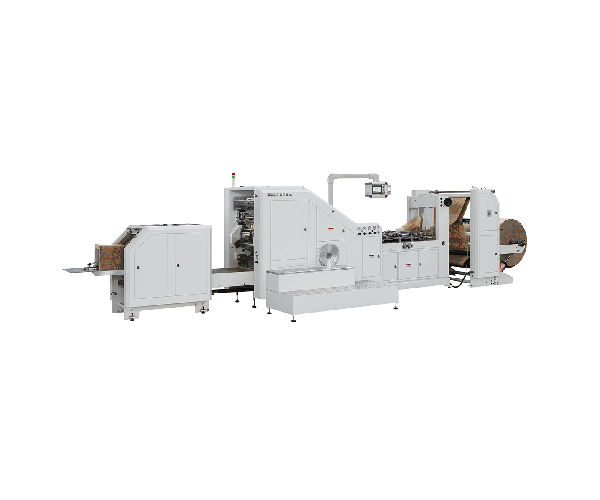

II. Automatic Square Bottom Paper Bag Machine

Square bottom bags (also known as SOS bags - "self-opening bags") are more durable and can stand upright, making them ideal for packaging heavier items.

Main Features:

Forms a strong square or rectangular base

High-speed production, automatic folding and gluing

Suitable for kraft paper, recycled paper and composite materials

Applications:

Grocery and shopping bags

Fast food packaging

Retail goods bags

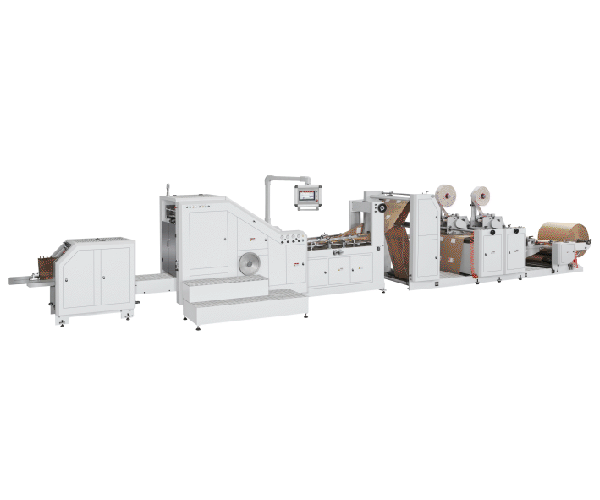

III. Bag Gluing Machine

Gluing bags are commonly used for industrial packaging, especially for powdered or granular products such as cement, flour and chemicals.

Main Features:

Forms valve opening for easy filling and sealing

Reinforced seams for heavy packaging

Highly automated with minimal human intervention

Applications:

Cement and building material packaging

Agricultural products (feed, fertilizer)

Food industry (flour, sugar, spices)

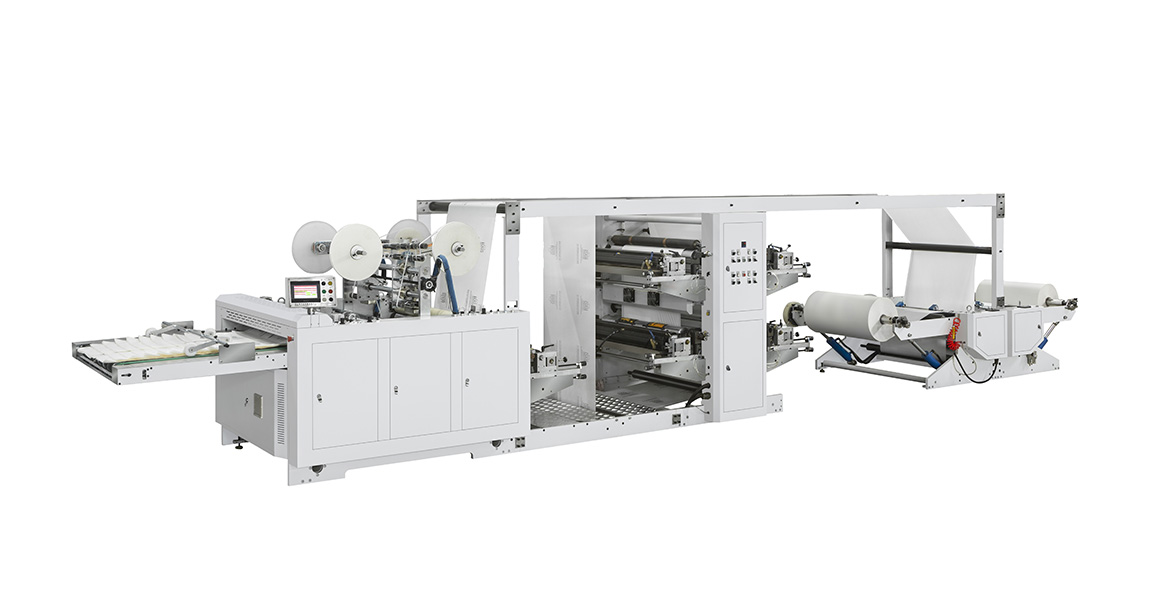

IV. Multi-layer paper bag machine

Multi-layer paper bags are composed of multiple layers of paper for extra strength and protection, and are commonly used in industrial and bulk packaging.

Main Features:

Can produce 2-6 layers of high durability paper bags

Can add lining to protect against moisture

Can customize printing options

Applications:

Bulk packaging for grains, seeds and chemicals

Building materials

Pharmaceutical packaging

V. Paper bag machine with handles

Paper bags with handles are popular in fashion boutiques, gift shops and high-end retail stores because they are easier to carry and are more conducive to branding.

Main Features:

Can add flat or twisted paper handles

Can integrate rope or ribbon handles

High-speed printing and customization

Applications:

Luxury shopping bags

Gifts and high-end packaging

Branded promotional bags

VI. Food-grade paper bag machine

These machines produce food-safe paper bags with an oil-proof coating and are commonly used in bakeries, fast food chains and take-out services.

Key Features:

Food-grade paper and eco-friendly inks

Optional wax or PE coating for enhanced oil resistance

FDA and food safety compliant

Applications:

Fast food packaging

Bakery and pastry bags

Microwave-safe food bags

Conclusion

Choosing the right paper bag machine depends on the type of bags required, output and material specifications. From simple flat bags to industrial multi-layer bags, each machine is designed to meet specific packaging needs. Investing in the right machine ensures efficient, economical and high-quality output, which is essential for retail, food and industrial packaging businesses.