In the packaging industry, efficiency and printing quality are critical to paper bag production. Whether it is for retail shopping, food packaging or promotional purposes, companies need reliable machines that can accurately handle high-speed printing and bag making.

This article explores the best machines for paper bag printing, focusing on high-speed printing bag making machines, square bottom paper bag machines and flexographic printing machines.

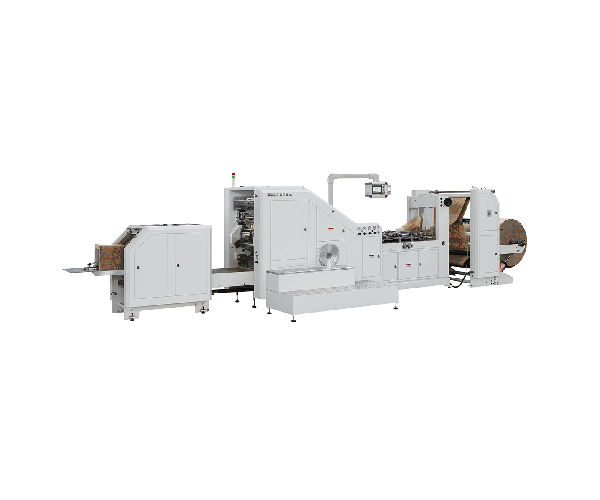

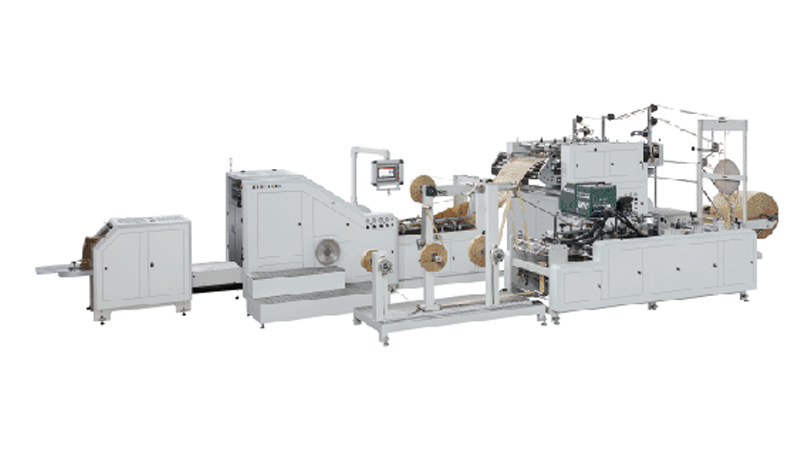

1. High-speed printing bag making machines (integrated solutions)

High-speed printing bag making machine combine printing and bag making production in one automated process, significantly improving efficiency.

Main features:

Fully automated - from web feeding to printing, folding, gluing and cutting.

120-260 bags per minute - ideal for large-scale production.

Servo motor control and touch screen interface - easy operation and quick adjustments.

Precise color tracking - ensure consistent print quality.

Best use

Mass production of shopping bags, food bags and gift bags.

Businesses that need fast turnaround time without sacrificing quality.

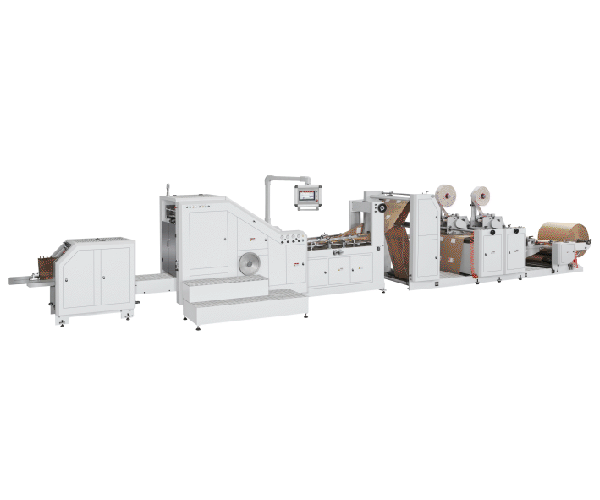

2. Square Bottom Paper Bag Machine (with optional printing unit)

Square Bottom Paper Bag Machine specializes in producing flat bottom paper bags, which are popular in retail and luxury packaging.

Key Features

One-step forming – printing, folding, bottom sealing and cutting are done in one go.

Quick size adjustment – easily switch between bags of different sizes.

High speed operation – can produce up to 260 bags per minute.

Ceramic Anilox Roller (optional) – improves print durability and color vibrancy.

Best Uses

Premium shopping bags (branded retail, fashion, cosmetics).

Eco-friendly paper bags (recyclable and biodegradable materials).

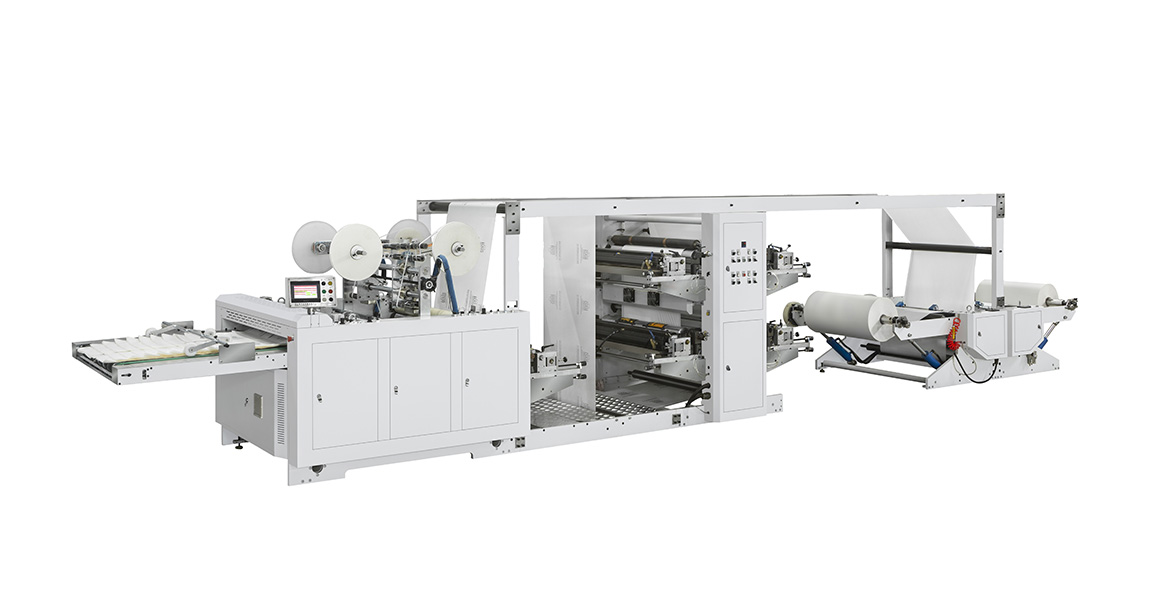

3. Flexographic Printing Machine (for custom printing on paper and film)

Flexographic printing machine (flexographic printing machine) is widely used for high-quality printing on paper, plastic film and composite materials before making bags.

Key Features

Multiple material compatibility – Works with kraft paper, PP, PE and aluminum foil.

Quick-drying ink – Reduces smudging and speeds up production.

High-resolution printing – Supports multi-color design and branding.

Low waste and cost-effective – Ideal for medium to large print runs.

Best for:

Custom printed paper bags (logos, graphics, promotional designs).

Food-safe packaging (meets industry standards).

Which machine should you choose?

| Machine Type | Best For | Speed | Print Quality |

| High-speed Printing Bag Making Machine | All-in-one Printing and Bag Making | 120-260 bags/minute | High |

| Square Bottom Paper Bag Machine | Premium Flat Bottom Bags | Up to 260 bags/minute | Medium to High |

| Flexo Printing Machine | Custom Design for Various Materials | Adjustable | Very High |

Conclusion

For businesses looking to efficiently print and produce paper bags, the best choice depends on production needs:

Fully Automatic High-speed Production - High-speed Printing Bag Making Machine

Premium Flat Bottom Bags - Square Bottom Paper Bag Machine

High-quality Custom Printing - Flexo Printing Machine