Paper bags have become an essential part of modern packaging due to their environmentally friendly properties and versatility. With increasing environmental awareness, businesses and consumers are shifting from plastic bags to paper bags, which is driving the need for efficient production machinery. This article explores the origin of most paper bags and highlights China's dominance in the field of paper bag machinery manufacturing, including paper bag handle machinery producers and kraft paper bag machinery suppliers.

I. China: Leading Paper Bag Production Hub

China is the world's largest paper bag producer, supplying finished paper bags and manufacturing machinery to the world. China's advanced industrial infrastructure, cost-effective labor force and technological innovation make it a key player in the paper packaging industry.

China's main contributions to the paper bag manufacturing industry:

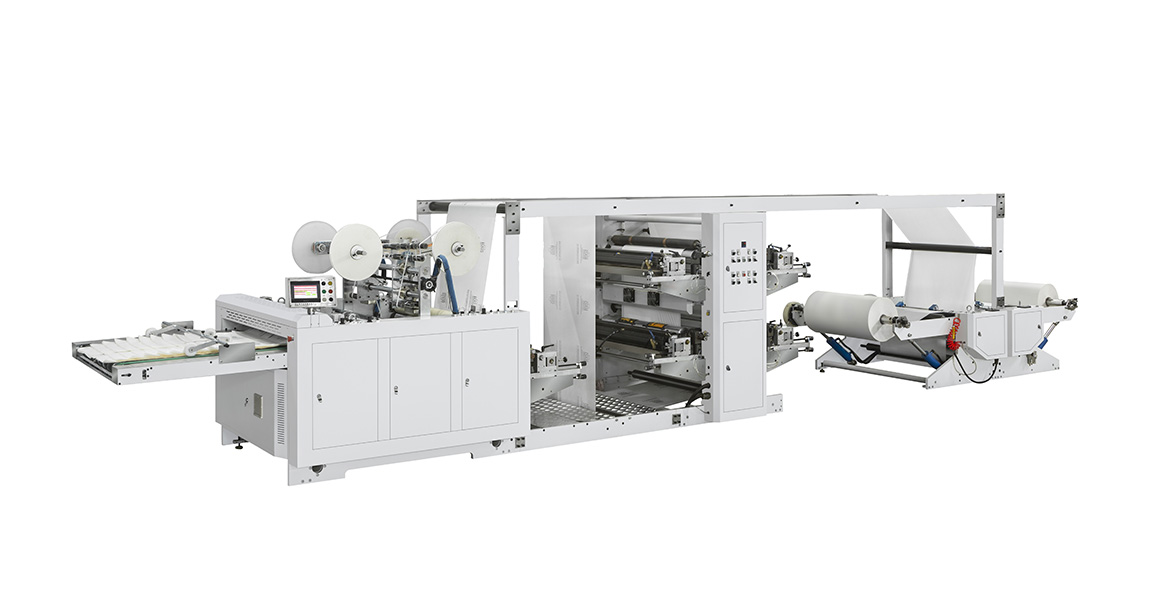

Chinese paper machine manufacturers: China produces high-quality paper bag machines, including fully automatic and semi-automatic models to meet the needs of different production scales.

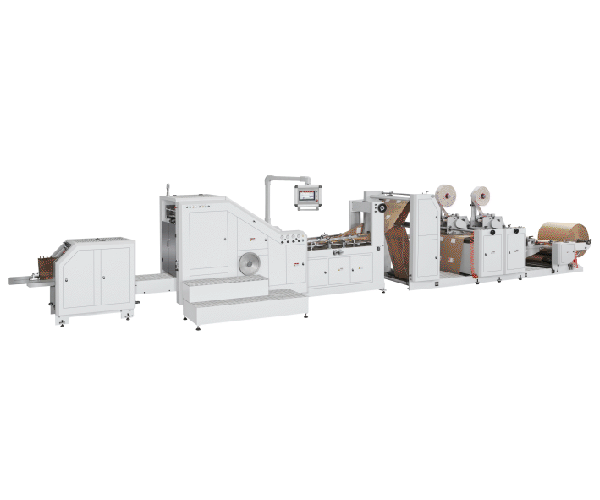

Paper bag handle machine manufacturers: China widely produces specialized machines for installing handles (flat handles, twisted handles or rope handles), ensuring the durability and efficiency of the equipment.

Kraft Paper Bag Machine Suppliers: Kraft paper is known for its high strength and sustainability and is widely used in shopping bags, food packaging, and gift bags. Chinese manufacturers offer advanced Kraft Paper Bag Machines that increase production speed and precision.

Major Chinese cities such as Guangzhou, Shanghai, and Dongguan are home to numerous factories and trade shows such as the *China International Paper Technology Exhibition*, which showcase the latest innovations in paper bag manufacturing.

II. Other major paper bag production regions

While China leads in paper bag production, other regions have also made significant contributions:

Europe: Countries such as Germany and Italy are known for their high-precision paper bag machines that focus on sustainability and automation.

India: The market for environmentally friendly packaging is growing, and the demand for Kraft Paper Bag Machines is also increasing.

North America: The United States and Canada place an emphasis on recycled paper bags, and manufacturers are investing in advanced machines to meet environmental regulations.

III. Factors driving the development of the paper bag industry

Environmental regulations: Bans on single-use plastics have prompted companies to turn to paper alternatives.

Consumer Preference: Environmentally conscious consumers prefer biodegradable and recyclable paper bags.

Technological Advances: Automation in Paper Bag Machine Manufacturing Improves Efficiency and Reduces Costs.

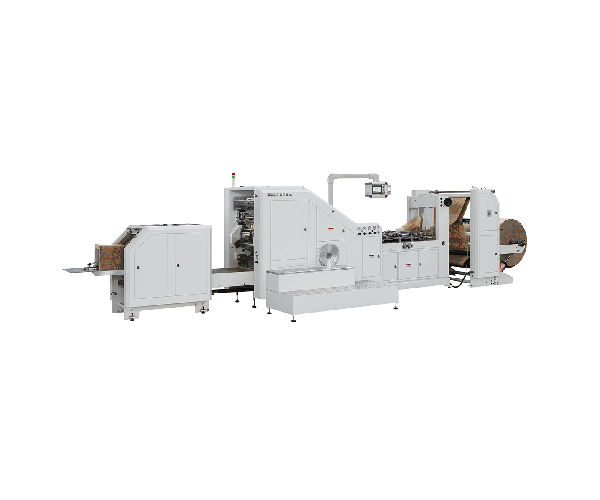

IV.China Paper Bag Machine Manufacturer - Lilin

Lilin is honored to be involved in the production of paper bag machines. As a Chinese paper bag machine manufacturer with 18 years of R&D and production experience, we have witnessed the changes and development of the industry.

With excellent quality, diverse configurations and professional technical support, our products have been sold to more than 70 countries and regions including Southeast Asia and South America, which fully demonstrates our global influence and our firm commitment to providing the best value to our valued customers. If you are considering choosing a paper bag machine, you might as well tell me your needs and our professional technicians will recommend a paper bag machine that meets your production needs online.

Conclusion

Today, most paper bags are produced in China, thanks to China's strong paper bag machine manufacturing industry. With the leading paper bag carrier manufacturer and kraft paper bag machine supplier, China remains the backbone of global paper bag production. As the trend towards sustainable development continues, demand for advanced paper bag machinery will continue to grow, cementing China’s key position in the industry.

For companies looking to invest in paper bag production, sourcing high-quality machinery from reputable Chinese manufacturers will ensure cost-effectiveness and scalability in this booming market.