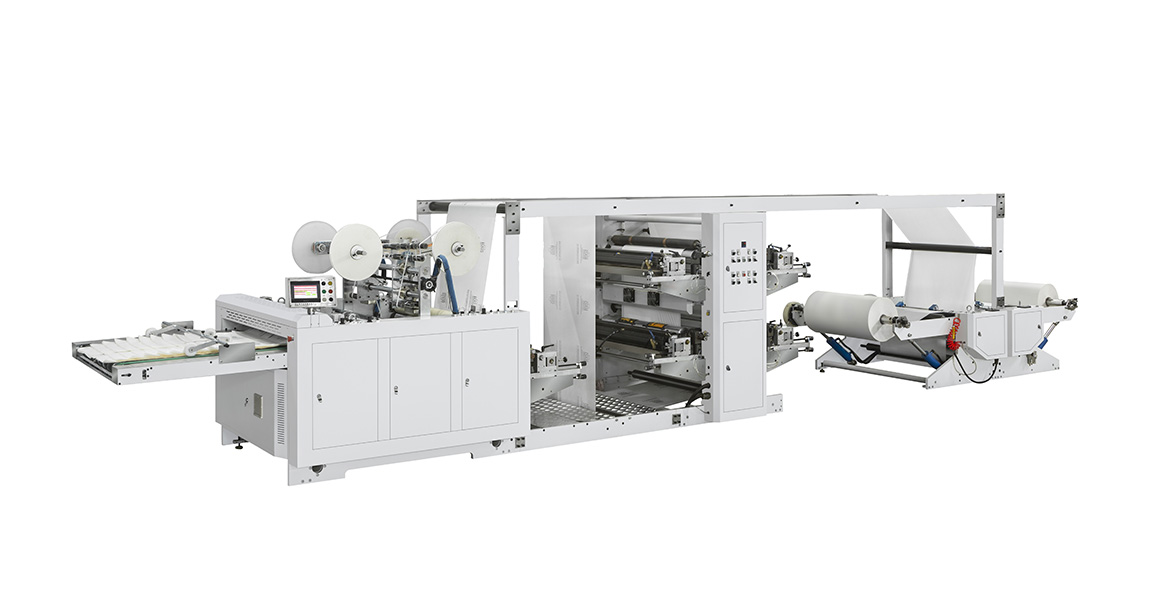

The machine is designed to complete the process of printing, partial gluing, bonding, pasting sealing tape, double-line cutting, cutting, and outputting finished bags in one go using original color roll paper. This model of machine is more convenient, efficient, and stable, suitable for producing various environmentally friendly packaging paper bags such as different paper packaging bags, clothing packaging bags, small household appliance packaging bags, fruit packaging bags, and so on.

1. Adopt touch screen and PC control system, the work condition can be shown real time.

2. Equipped with accurate servo motor drive, it makes the machine run steadily and efficiently.

3. Using a rotating hob for cutting, the cutting is smooth and efficient.

4. Material lifting adopt pneumatic lift structure.

5. Automatic constant tension control system. The tension will be just right from beginning to end.

6. Double photoelectric sensor limit automatic correction control system

7. Ink-ring sealed scraping knife scraping.

8. Ink Ceramic Anilox roller, high speed dot rate, screen printed layered, stronger.

9. Button-360 ° continuous and adjustable longitudinal register device.

10. pneumatic automatic printing plate roller.

|

Type |

LES-1100+LST-41100 |

||

|

Cutting Length (L) |

180-620 mm |

|

|

|

Bag Width (W) |

200-1100 mm |

|

|

|

Max. Speed |

single line |

150 pcs/min |

|

|

|

double line |

300 pcs/min |

|

|

Max. reel weight |

600 Kg |

|

|

|

Max.Roll Diametr |

1200 mm |

|

|

|

Reel inner diameter |

76 mm |

|

|

|

Paper specification |

30-150 gsm |

||

|

Printing Color |

2+2 Color |

||

|

Printing Width |

1100 mm |

||

|

Printing Length |

180-800 mm |

||

|

Max.Printing Speed |

120 m/min |

||

|

Overprint Precision |

±0.15 mm |

||

|

Thickness of Plate |

1.7 mm |

||

|

Web edge control system |

Double photoelectric automatic correction control system |

||

|

Web tension control system |

automatic constant tension control system |

||

|

coating way |

coated with cold glue |

||

|

Air pressure |

≥0.12cmm, 0.4~1Mpa |

||

|

Driven motor |

Six servo motor |

||

|

Electric |

380V, 50Hz, 3 phase |

||

|

Power |

25 KW |

||

|

Weight |

5500 Kg |

||

|

Overall dimension |

10500×1800×1850 mm |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note:Please contact us for more product details.

Get A Quote !