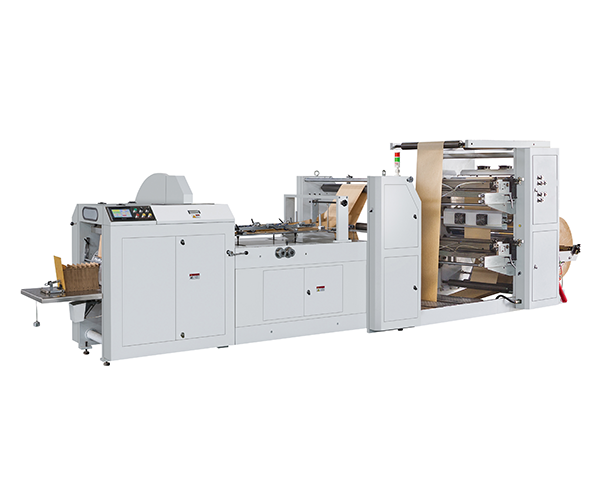

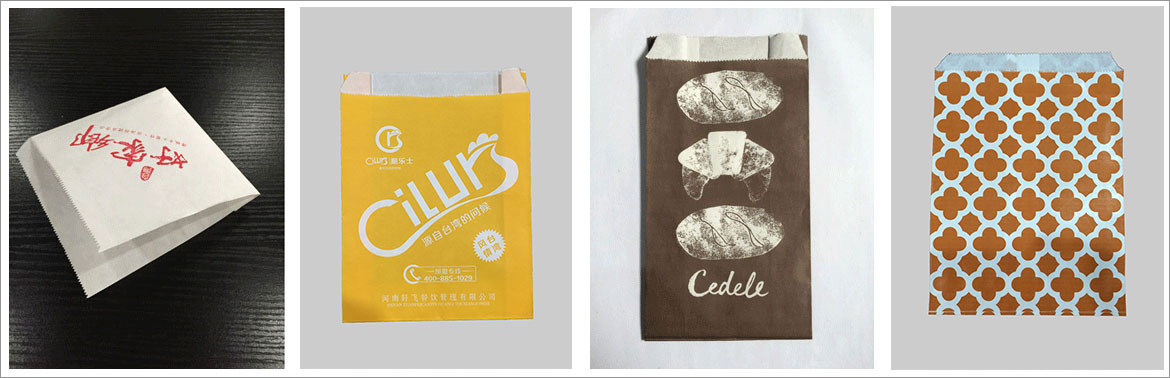

This machine forming the paper bag in one process from roll paper, printing, edge folding, tube forming, cutting, gluing, bottom folding,bottom gluing and finishing bag Easy operation, low power consumption, high efficiency. It is an ideal machine for producing food bags like bread bags, KFC bags and Mcdonald’s bags.

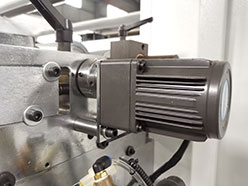

1.Adopting frequency converter stepless speed regulation.

2.Independent glue coating system, the glue coating system can be run independently after the machine stops.

3.The integral paper tube forming adjustment structure can be adjusted at the same time with one side or two sides.

4.Material lifting adopt pneumatic lift structure.

5.Automatic constant tension control system. The tension will be just right from beginning to end.

6.Lift and lower the printing plate cylinder Automatic, it will automatically stir the printing ink after lifting.

7.button-360 °continuous and adjustable longitudinal register device.

| Type | LMD-600G+LST-2700J |

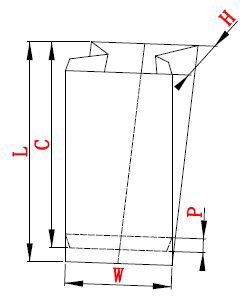

| Cutting Length(C) | 220-620 mm |

| Bag Length(L) | 210-610 mm |

| Bag Width(W) | 70-280 mm |

| Gusset Thickness(H) | 0-120 mm |

| Standard Flap(P) | 12-20 mm |

| Max.Speed | 500 pcs/min |

| Paper Thickness | 30-80 gsm |

| Paper Roll Width | 220-700 mm |

| Max.Roll Diameter | 1100 mm |

| Reel Inner Diameter | 76 mm |

| Printing Color | 2 Color |

| Printing Width | 700 mm |

| Printing Length | 180-800 mm |

| Max.Printing Speed | 80 m/min |

| Overprint Precision | ±0.15 mm |

| Thickness of Plate | 1.7 mm |

| Total Power | 4kw |

| Weight of Machine | 4300 kg |

| Overall Dimension(LxWxH) | 6900×1550×1850 mm |

Note:

Machine speeds dependent on paper & adhesive qualities, bag dimensions, operator knowledge, and general work philosophy.

Frequency control of motor speed Frequency control of motor speedAdopting frequency converter stepless speed regulation, the acceleration and deceleration smooth control is simple. |

Independent glue coating system Independent glue coating systemIndependent glue coating system, the glue coating system can be run independently after the machine stops, avoiding the glue drying and not easy to clean. The glue tank is glued to the bottom to prevent glue from dripping. |

Safety shield Safety shieldCutter safety shield protection switch can avoid the danger that user forgets to close the shield when machine runs with high speed. |

|

|

|

|

Independent group automatic ink system Independent group automatic ink systemIndependent group automatic ink system, avoid stopping too long after drying of the ink roller outlets blocked, affecting print quality, ink system will automatically turn on when the machine stops, can be opened one or more sets of ink |

Get A Quote !