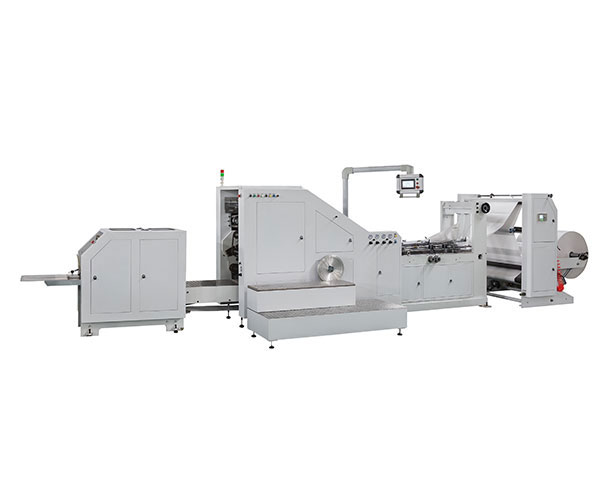

Working Flow Chart - Unwinder paper rolls feeding -epc -auto tension -Side Glue -Photocell-Forming tube-Gusset -Pulling paper -Cutting -Creasing -Square bottom shape forming -Bottom glue -Finished Square bottom paper bags

Roll Feeding square bottom paper bag making machine forming the paper bag in one process from printed or unprinted roll paper , side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke.

Roll Feeding square bottom paper bag making machine forming the paper bag in one process from printed or unprinted roll paper , side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke. This machine controls by PC programmable servo motor through the human-machine touch screen interface. It can produce various of specifications paper bags. This machine have advantages of high speed, quickly replace the paper bag specifications, more wide range adjusting etc. It is an ideal machine for producing food bag, shopping handles bag.

1.The human-machine touch screen interface, the work condition can be shown in real- time.

2.Equipped with accurate servo motor drive, it makes the machine run steadily and efficiently.

3.Material lifting adopt pneumatic lift structure.

4.“foolproof” style automatic constant tension control system using the United Stated Bellofram precision controller. The tension will be just right from beginning to end.

5.Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving, long life.

6.Thumb buttons, appressed bottom cutting device, bag type have many choices.

7.Don't stop machine adjust double bottom structure, the adjustment will become more intuitive, more simple, more time saving.

8.Glue roller air defense coating control, avoid gluing on besmear brushes hub surface directly, reduce unnecessary trouble.

9.Accurate color tracking system, color errors automatically shut down.

10.Automatic lubricating oil supply system.

12.Paper Folding Machine Processing Type and ISO 9001 Certification Paper cement bag making machine

13.paper bag machine fully automatic

14. making machine Kind cost of paper bag making machine

15.Paper Bag Making Machine With Flexo Printing

16. Paper Material and Shopping Bag Bag Type Paper Bag Making Machine

17.Full Automatic High Speed Paper Bag Making Machine

18.Paper Material and Bag Forming Machine Machine Type paper carry bag

|

Type |

LSB-450 |

|

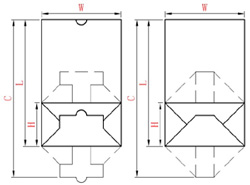

Bag Width(W) |

260-450 mm |

|

Bottom Size(H) |

85-180 mm |

|

Bag tube length(C) |

270-530 mm |

|

Max.Speed |

180 pcs/min |

|

Paper Thickness |

80-180 gsm |

|

Paper Roll Width |

700-1250 mm |

|

Max.Roll diameter |

1200 mm |

|

Reel inner diameter |

76 mm |

|

Total Power |

12 Kw |

|

Weight of Machine |

7000 kg |

|

Overall Dimension(LxWxH) |

8300×2750×1800 mm |

|

|

|

|

|

|

|

|

|

|

|

|

Get A Quote !