The development of digital printing technology gives food packaging more possibilities. Kraft paper is often used when customizing food packaging bags. Different pointed bottom paper bags will be customized according to the food use of the paper bag and the weight of the packaging to meet the needs of customers. need.

Kraft paper is made from coniferous kraft natural pulp, which is strong and usually yellowish brown, in addition to light brown, cream or white. In general, the thickness is 80 grams to 120 grams. And kraft paper has a very strong pulling force, there are single light, double light, stripes, no lines and so on. Main application places, food takeaway bags, chestnut dried fruit packaging bags, bread bags, envelope bags, file bags, medical record bags and other occasions.

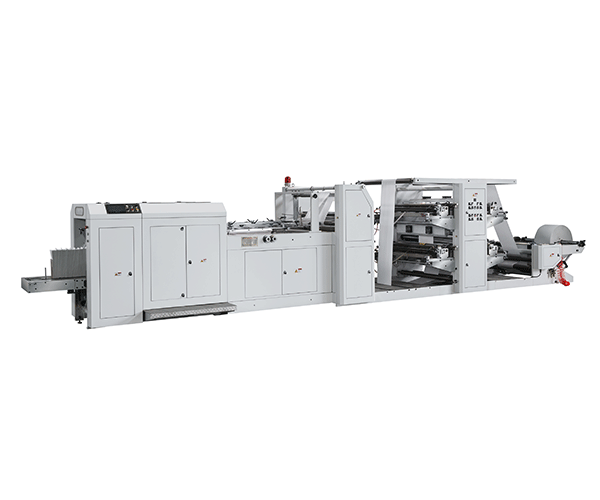

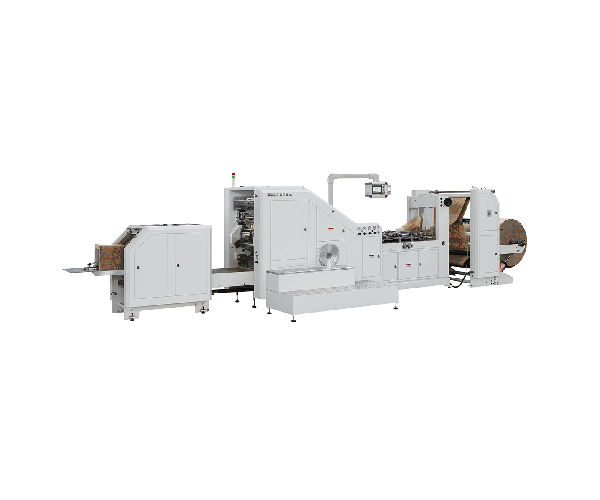

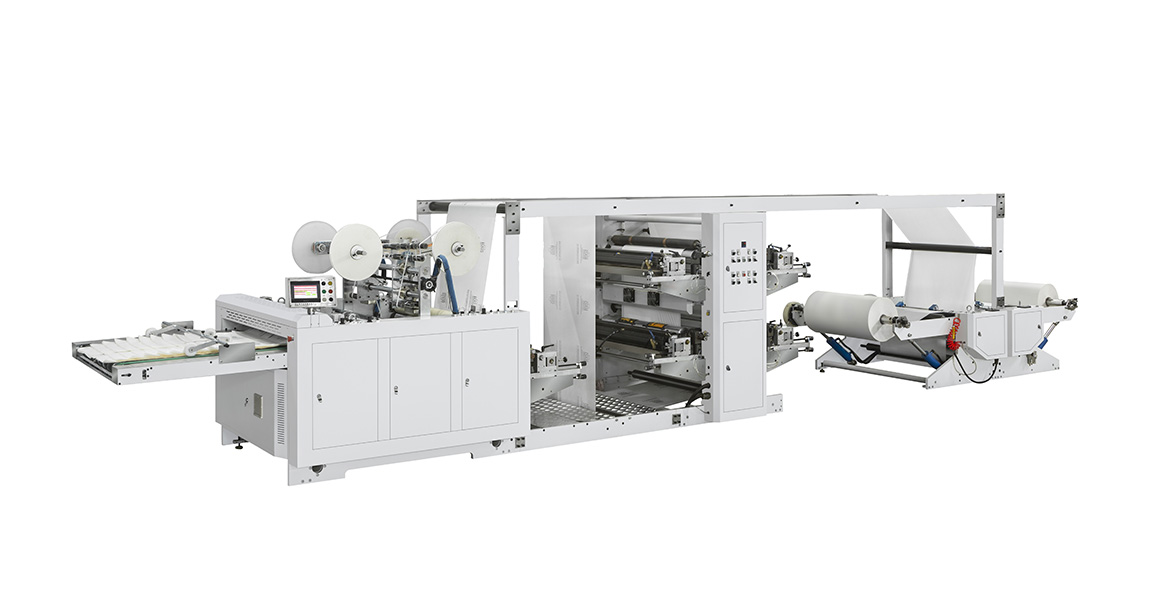

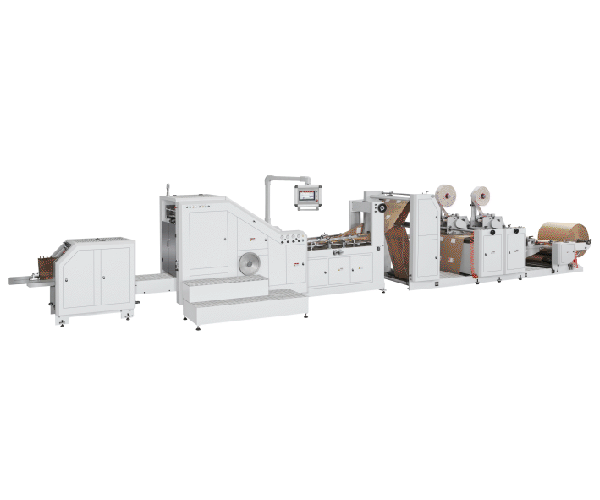

The pointed bottom paper bag machine is suitable for PCB batch production, stable, high-quality, high-speed, and the production capacity has achieved breakthroughs. The fastest machine is 700 pieces/min, which can reduce labor costs. The bottom paper bag machine can complete the side gluing, folding into micro, cutting the paper tube, gluing the bottom, forming the bottom of the bag, unloading the bag, and the whole machine is controlled by the computer to control the length of the paper bag.